Dr. Dmitri Kopeliovich

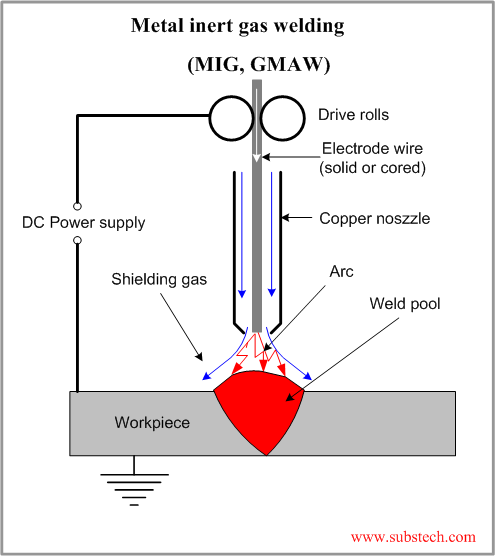

Metal Inert Gas Welding (Gas Metal Arc Welding) is a arc welding process, in which the weld is shielded by an external gas (Argon, helium, CO2, argon + Oxygen or other gas mixtures).

Consumable electrode wire, having chemical composition similar to that of the parent material, is continuously fed from a spool to the arc zone. The arc heats and melts both the work pieces edges and the electrode wire. The fused electrode material is supplied to the surfaces of the work pieces, fills the weld pool and forms joint.

Due to automatic feeding of the filling wire (electrode) the process is referred to as a semi-automatic. The operator controls only the torch positioning and speed.

Advantages of Metal Inert Gas Welding (MIG, GMAW):

- Continuous weld may be produced (no interruptions);

- High level of operators skill is not required;

- Slag removal is not required (no slag);

Disadvantages of Metal Inert Gas Welding (MIG, GMAW):

- Expensive and non-portable equipment is required;

- Outdoor application are limited because of effect of wind, dispersing the shielding gas

No comments:

Post a Comment